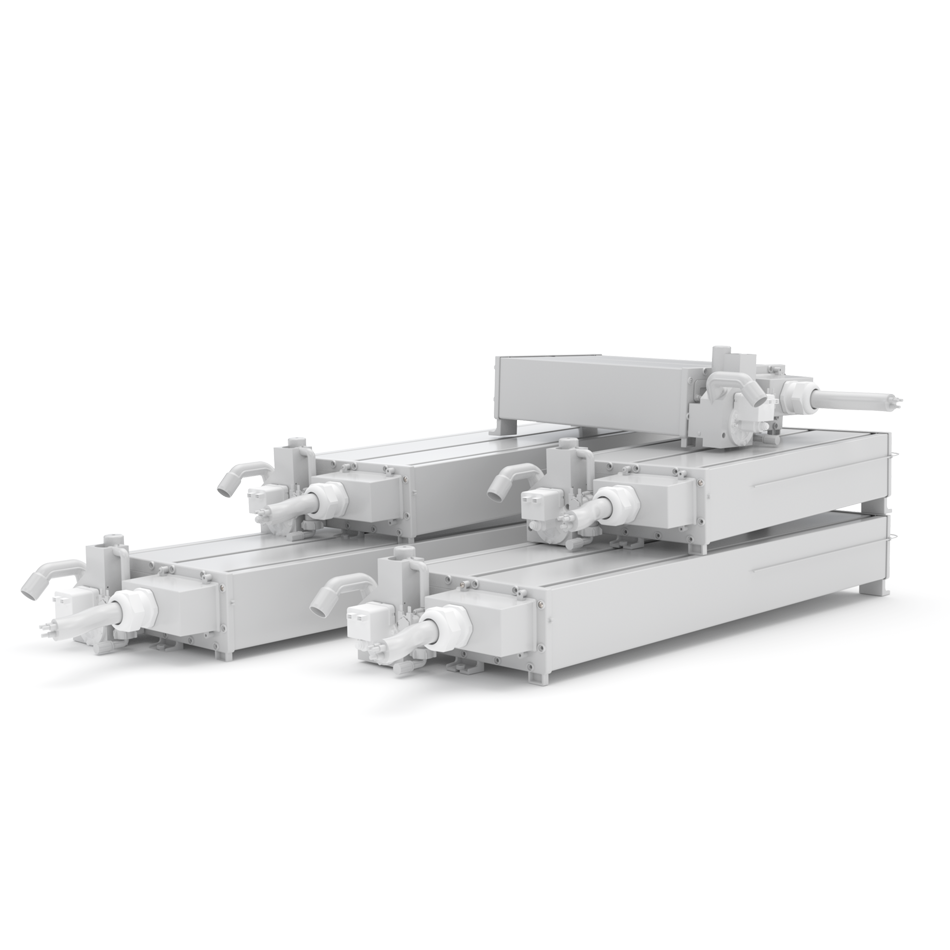

Flexibility

Various sizes available, so it adapts easily to the size of the air handling unit

Maximum efficiency

- Hydraulic unit in AHU

- No loss of load

- No condensate in the steam distribution systems

- Helps heat the room

- No loss of load

- No condensate in the steam distribution systems

- Helps heat the room

Germ-free steam

Self-extinguishing engineering plastic which prevents bacterial proliferation

Installed directly in an AHU

No need for an electronics compartment or distribution piping

OEMs series

- Modular solution for AHU manufacturers consisting of 1 or 2 boilers that can be combined with the same steam emission (e.g. 2 x 60kg/h, 2 x 80kg/h, 2 x 100kg/h) to reach the desired production capacity

- Independent configuration of power supply voltage

- Freedom for the OEM to define the electrical layout

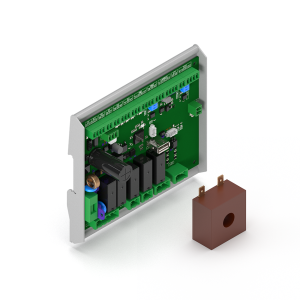

Electronic controller and current transformer

EHHKT and 0103349007

- Controller kit with an open frame board which can be housed in the AHU electrical panel

- Suitable for all boiler sizes

- To be ordered separately

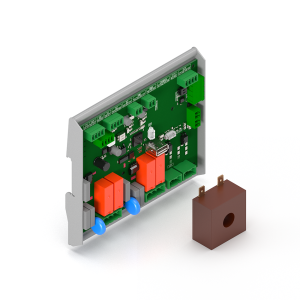

EHHKX and 0103349007

Expansion board and current transformer to control an additional hydraulic unit

Ideal in the following applications

| EHKD | 010T4XS | 010T5XS | 020T4S | 020T5S | 020T4XS | 020T5XS | 030T4M | 030T5M | 030T4S | 030T5S | 040T4L | 040T5L | 040T4S | 040T5S | 060T4XL | 060T5XL | 060T4M | 060T5M | 080T4L | 080T5L | 100T4XL | 100T5XL |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| STEAM PRODUCTION | ||||||||||||||||||||||

| Production capacity [kg/h] | 10 | 20 | 30 | 40 | 60 | 80 | 100 | |||||||||||||||

| ELECTRICAL PROPERTIES | ||||||||||||||||||||||

| Power consumption [kW] | 7.5 | 15 | 22.5 | 30 | 45 | 60 | 75 | |||||||||||||||

| Power supply [Vac, Hz] | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 |

| Phases [n] | 3 | |||||||||||||||||||||

| Current per phase [A] | 10.8 | 9.4 | 21.7 | 18.8 | 22 | 18.8 | 32.5 | 28.2 | 32 | 28.2 | 43.3 | 37.7 | 40 | 37.7 | 65 | 56.5 | 65 | 56.5 | 87 | 75.3 | 108.2 | 94.1 |

| WATER PROPERTIES | ||||||||||||||||||||||

| Inlet water quality | Complies with microbiological standards for drinking water established by regulations in force where installed. Partially demineralised water may be used |

|||||||||||||||||||||

| Inlet water conductivity [μS*cm] | 75…1250 | |||||||||||||||||||||

| Inlet water hardness [°f] | 5...50 | |||||||||||||||||||||

| Inlet water pressure [MPa/bar] | 0,02...1/0,2...10 | |||||||||||||||||||||

| Minimum instantaneous flow rate of inlet water [l/min] | 3.5 | 5.5 | 3.5 | 5.5 | 3.5 | 5.5 | ||||||||||||||||

| Inlet water connection | M 3/4"GAS | |||||||||||||||||||||

| Water drain external diameter [mm] | 40 | |||||||||||||||||||||

| GENERAL CHARACTERISTICS | ||||||||||||||||||||||

| Control unit dimensions [mm] | 350x500x210 | |||||||||||||||||||||

| Hydraulic unit dimensions [mm] | 330x167 | |||||||||||||||||||||

| Depth 4 electrodes [mm] | 635 | 785 | / | 985 | / | 1185 | / | 1385 | / | / | / | |||||||||||

| Depth 7 electrodes [mm] | / | / | 635 | / | 785 | / | 785 | / | 985 | 1185 | 1385 | |||||||||||

| Weight [kg] | 15 | 16.5 | 18.5 | 21.5 | 25 | 24.5 | 27.5 | 30 | ||||||||||||||

| Operating conditions [°C, RH] | 1…40, max. 80% non-condensing | |||||||||||||||||||||

| Storage conditions [°C, RH] | -10…70, max. 95% non-condensing | |||||||||||||||||||||

| Level of protection of control unit | IP65 | |||||||||||||||||||||

| Level of protection of hydraulic unit | IPX0 | |||||||||||||||||||||

| REGULATION | ||||||||||||||||||||||

| Type of controller | Built-in | |||||||||||||||||||||

| Command signal | ON-OFF, proportional 0...10 V, transducer 0...10 V/4...20 mA | |||||||||||||||||||||

| Connectivity | ||||||||||||||||||||||

| RS-485 MODBUS | Built-in | |||||||||||||||||||||

| Condensate collection trays | |

| 0016020018 | stainless steel condensate collection tray 490x690x70 mm |

| 0016020019 | stainless steel condensate collection tray 490x950x70 mm |

| 0016020020 | stainless steel condensate collection tray 490x1.350x70 mm |

| EHVI | drainage tank Zephyr, KT and VEH series humidifier |

| EHKD0K18 | 5 m long power supply cable kit between panel and hydraulic unit for EHKD010-EHKD020-EHKD030-EHKD040-VEH10-VEH20-VEH30-VEH40 |

| EHKD0K19 | 5 m long power supply cable kit between panel and hydraulic unit for EHKD060-EHKD080-EHKD100-VEH60-VEH80-VEH100 |

| EHKD0K20 | hydraulic unit accessibility kit for VEH series humidifiers from air treatment units |

| EHKD0K22 | wall-mounted hydraulic connection kit for VEH series humidifiers |

| EHKD0K23 | VEH series humidifier water loading/unloading external kit |

| Controls | |

| EV3411M7 | single output electronic controller, power supply 230 VAC, multi-sensor analog input |

| EVHTP520 | humidity and temperature probe, proprietary signal |

| EVHP523 | humidity transducer, power supply 8... 28 VDC, 1 x 4-20 mA provided signal |

| EVHTP523 | humidity and temperature transducer, power supply 8... 28 VDC, 2 x 4-20 mA provided signal |

| EVTPNW30F200 | NTC probe, 2 wires thermoplastic cable 3 m lenght, 5x20 mm overmoulded bulb, IP68 protection |

| Various | |

| 0031000048 | 0.3 m long flexible hose ¾ " GAS female that connects the mains water and solenoid valve to load water |