Flexibility

Maximum efficiency

- No loss of load

- No condensate in the steam distribution systems

- Helps heat the room

Germ-free steam

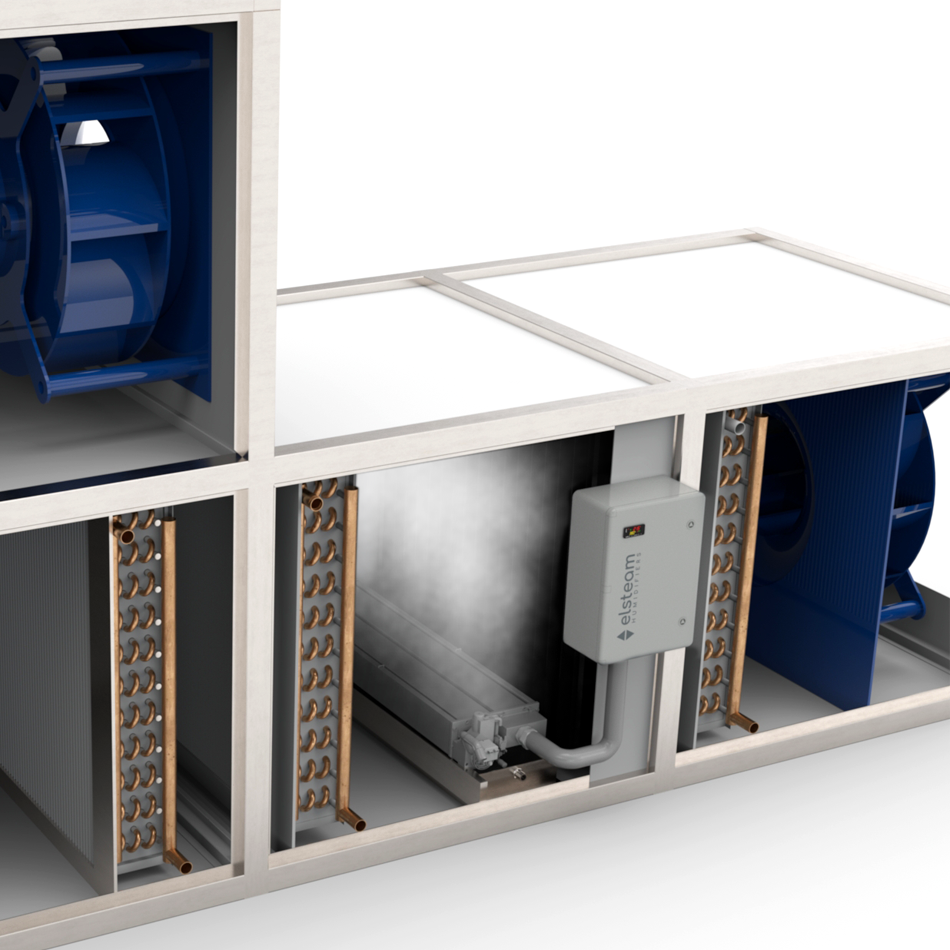

Installed directly in an AHU

Choose the most suitable version for your AHU

Models are available with 4 or 7 electrodes of different depths and steam production capacity that goes from 10 to 100 kg/h, making the VEH series easy to adapt to the size of the AHU.

A range of accessories is available to customise the size and accessibility of the hydraulic unit.

- Tank in self-extinguishing engineering plastic and in compliance with Method A and Method C of ISO 846

- Automatic draining system with 40 mm diameter

- Protects against flooding in the AHU

- Microprocessor controller with LED user interface

- Connection for RS-485 protocol for remote control in MODBUS mode

- Mechanical parts designed to simplify use and maintenance

Separate plumbing and control

The standout feature of the VEH series is that each model is made up of two separate units: a hydraulic unit in self-extinguishing engineering plastic which is ISO 846 certified (it is installed directly in the AHU, it has no distribution piping for optimal steam release and helps heat the room) and an electrical control unit with IP65 protection which requires no electronics compartment.

Positioning enhances efficiency

Placing VEH humidifiers inside air handling units means energy savings: not only does the 100 °C steam help with heating, it is also produced exactly where it is needed, preventing the formation of condensate and the loss of load due to back pressure, which can occur when steam is conveyed from its point of production to its place of distribution. And when AHUs are installed outdoors, placing the humidifier inside means no protective casing is needed for it.

Ideal in the following applications

| EHKD | 010T4XS | 010T5XS | 020T4S | 020T5S | 020T4XS | 020T5XS | 030T4M | 030T5M | 030T4S | 030T5S | 040T4L | 040T5L | 040T4S | 040T5S | 060T4XL | 060T5XL | 060T4M | 060T5M | 080T4L | 080T5L | 100T4XL | 100T5XL |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| STEAM PRODUCTION | ||||||||||||||||||||||

| Production capacity [kg/h] | 10 | 20 | 30 | 40 | 60 | 80 | 100 | |||||||||||||||

| ELECTRICAL PROPERTIES | ||||||||||||||||||||||

| Power consumption [kW] | 7.5 | 15 | 22.5 | 30 | 45 | 60 | 75 | |||||||||||||||

| Power supply [Vac, Hz] | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 |

| Phases [n] | 3 | |||||||||||||||||||||

| Current per phase [A] | 10.8 | 9.4 | 21.7 | 18.8 | 22 | 18.8 | 32.5 | 28.2 | 32 | 28.2 | 43.3 | 37.7 | 40 | 37.7 | 65 | 56.5 | 65 | 56.5 | 87 | 75.3 | 108.2 | 94.1 |

| WATER PROPERTIES | ||||||||||||||||||||||

| Inlet water quality | Complies with microbiological standards for drinking water established by regulations in force where installed. Partially demineralised water may be used |

|||||||||||||||||||||

| Inlet water conductivity [μS*cm] | 75…1250 | |||||||||||||||||||||

| Inlet water hardness [°f] | 5...50 | |||||||||||||||||||||

| Inlet water pressure [MPa/bar] | 0,02...1/0,2...10 | |||||||||||||||||||||

| Minimum instantaneous flow rate of inlet water [l/min] | 3.5 | 5.5 | 3.5 | 5.5 | 3.5 | 5.5 | ||||||||||||||||

| Inlet water connection | M 3/4"GAS | |||||||||||||||||||||

| Water drain external diameter [mm] | 40 | |||||||||||||||||||||

| GENERAL CHARACTERISTICS | ||||||||||||||||||||||

| Control unit dimensions [mm] | 350x500x210 | |||||||||||||||||||||

| Hydraulic unit dimensions [mm] | 330x167 | |||||||||||||||||||||

| Depth 4 electrodes [mm] | 635 | 785 | / | 985 | / | 1185 | / | 1385 | / | / | / | |||||||||||

| Depth 7 electrodes [mm] | / | / | 635 | / | 785 | / | 785 | / | 985 | 1185 | 1385 | |||||||||||

| Weight [kg] | 15 | 16.5 | 18.5 | 21.5 | 25 | 24.5 | 27.5 | 30 | ||||||||||||||

| Operating conditions [°C, RH] | 1…40, max. 80% non-condensing | |||||||||||||||||||||

| Storage conditions [°C, RH] | -10…70, max. 95% non-condensing | |||||||||||||||||||||

| Level of protection of control unit | IP65 | |||||||||||||||||||||

| Level of protection of hydraulic unit | IPX0 | |||||||||||||||||||||

| REGULATION | ||||||||||||||||||||||

| Type of controller | Built-in | |||||||||||||||||||||

| Command signal | ON-OFF, proportional 0...10 V, transducer 0...10 V/4...20 mA | |||||||||||||||||||||

| Connectivity | ||||||||||||||||||||||

| RS-485 MODBUS | Built-in | |||||||||||||||||||||

| Condensate collection trays | |

| 0016020018 | stainless steel condensate collection tray 490x690x70 mm |

| 0016020019 | stainless steel condensate collection tray 490x950x70 mm |

| 0016020020 | stainless steel condensate collection tray 490x1.350x70 mm |

| EHVI | drainage tank Zephyr, KT and VEH series humidifier |

| EHKD0K18 | 5 m long power supply cable kit between panel and hydraulic unit for EHKD010-EHKD020-EHKD030-EHKD040-VEH10-VEH20-VEH30-VEH40 |

| EHKD0K19 | 5 m long power supply cable kit between panel and hydraulic unit for EHKD060-EHKD080-EHKD100-VEH60-VEH80-VEH100 |

| EHKD0K20 | hydraulic unit accessibility kit for VEH series humidifiers from air treatment units |

| EHKD0K22 | wall-mounted hydraulic connection kit for VEH series humidifiers |

| EHKD0K23 | VEH series humidifier water loading/unloading external kit |

| Controls | |

| EV3411M7 | single output electronic controller, power supply 230 VAC, multi-sensor analog input |

| EVHTP520 | humidity and temperature probe, proprietary signal |

| EVHP523 | humidity transducer, power supply 8... 28 VDC, 1 x 4-20 mA provided signal |

| EVHTP523 | humidity and temperature transducer, power supply 8... 28 VDC, 2 x 4-20 mA provided signal |

| EVTPNW30F200 | NTC probe, 2 wires thermoplastic cable 3 m lenght, 5x20 mm overmoulded bulb, IP68 protection |

| Various | |

| 0031000048 | 0.3 m long flexible hose ¾ " GAS female that connects the mains water and solenoid valve to load water |