Washable boiler

5 times less plastic at end of life

Versatile

Energy efficiency

Saves water

Accurate

- The overflow system protects against boiler overpressure and its value can be modified on request with an optional kit

- Pump-driven draining system which breaks the limescale deposit into small pieces for easy ejection

- Automatic boiler cleaning system

- Protection against water escaping on the steam side

- Boiler circuit and polymeric parts of the linear steam distributors are in self-extinguishing material

- No mechanical obstructions on the steam side and drain side

- Mechanical parts designed to simplify use and maintenance

- Connection for RS-485 protocol for remote control in MODBUS mode

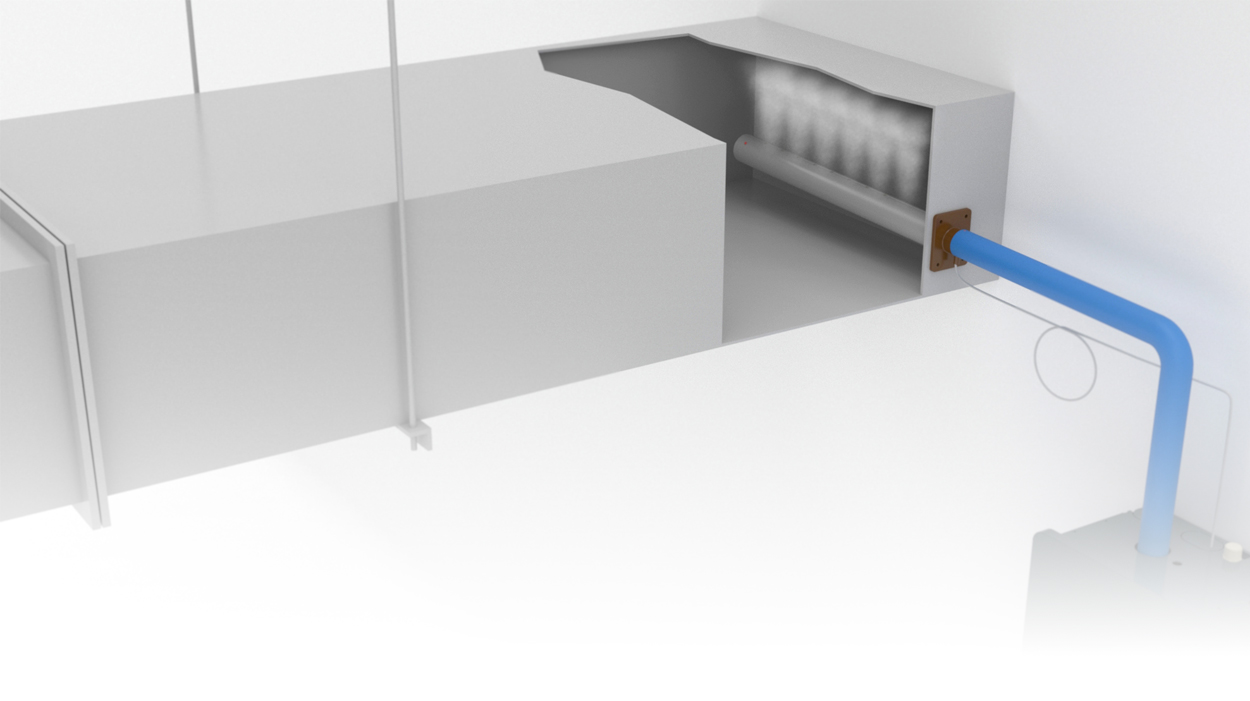

Steam distribution systems

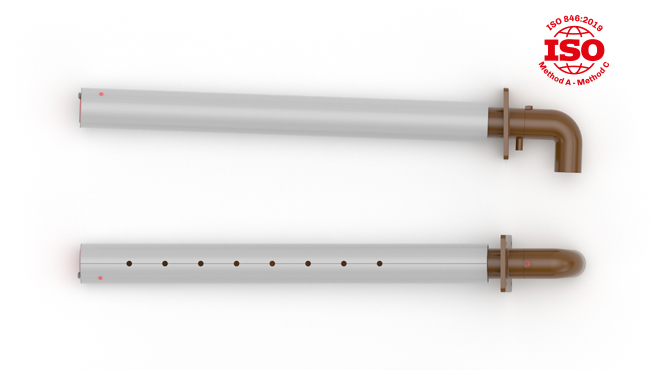

Linear distributors for ducts

Extruded linear distributor with reduced thermal transmittance

The surface in non-porous, waterproof engineering plastic prevents bacterial proliferation and complies with Method A and Method C of ISO846. It withstands sudden changes in temperature and chemicals, thus making it easy to sterilise.

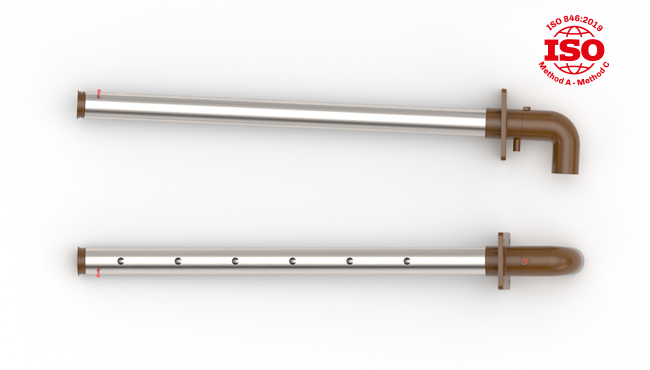

Stainless steel linear distributor

Stainless steel is a very hygienic material as it is corrosion resistant and its surface is compact and non-porous, making removing bacteria during cleaning and sterilisation easier.

Steam blower for room

This steam blower, which delivers steam directly into the room, is made of engineering plastic which prevents bacterial contamination and withstands chemical attack. Thanks to its thermal insulation, it is also energy efficient. The blower can be fitted directly onto the humidifier or placed in the room, according to the manufacturer’s instructions, using a special mobile support. The maximum steam flow is 15 kg/h.

Ideal in the following applications

| EHKX | 003M2 | 005M2 | 003T4 | 003T5 | 005T4 | 005T5 | 010T4 | 010T5 | 015T4 | 015T5 |

|---|---|---|---|---|---|---|---|---|---|---|

| STEAM PRODUCTION | ||||||||||

| Production capacity [kg/h] | 3 | 5 | 3 | 5 | 10 | 15 | ||||

| Maximum pressure [mm H2O/Pa/bar] | 165/1650/0,0165 | |||||||||

| Pipe connection external diameter [mm] | 38 | |||||||||

| ELECTRICAL PROPERTIES | ||||||||||

| Number of linear distributors that can be connected [n] | 1 | |||||||||

| Number of steam blowers that can be connected [n] | 1 | |||||||||

| ELECTRICAL PROPERTIES | ||||||||||

| Power supply [Vac, Hz] | 2.2 | 3.75 | 2.2 | 3.75 | 7.5 | 11.3 | ||||

| Power supply [Vac, Hz] | 230, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | |

| Phases [n] | 1 | 3 | ||||||||

| Current per phase [A] | 9.6 | 16.3 | 3.2 | 2.8 | 5.4 | 4.7 | 10.8 | 9.4 | 16.3 | 14.2 |

| WATER PROPERTIES | ||||||||||

| Inlet water quality | Complies with microbiological standards for drinking water established by regulations in force where installed. Partially demineralised water may be used | |||||||||

| Inlet water conductivity [μS*cm] | 70…1250 | |||||||||

| Inlet water hardness [°f] | 5...50 | |||||||||

| Inlet water pressure [MPa/bar] | 0.2...1 / 2...10 | |||||||||

| Minimum instantaneous flow rate of inlet water [l/min] | 1.2 | 2.2 | ||||||||

| Inlet water connection | M 3/4"GAS | |||||||||

| Water drain external dimensions [mm] | 40 | |||||||||

| GENERAL CHARACTERISTICS | ||||||||||

| Dimensions [mm] | 412x766x248 | |||||||||

| Operating conditions [°C, RH] | 1…40, max. 80% non-condensing | |||||||||

| Storage conditions [°C, RH] | -10…70, max. 95% non-condensing | |||||||||

| Degree of protection | IP20 | |||||||||

| REGULATION | ||||||||||

| Type of controller | Built-in with advanced EPcolor user interface | |||||||||

| Command signal | ON-OFF, proportional 0...10 V, transducer 0...10 V/4...20 mA | |||||||||

| Connectivity | ||||||||||

| RS485-MODBUS | Built-in | |||||||||

| EHKX | 020T4 | 020T5 | 030T4 | 030T5 | 040T4 | 040T4 | 060T4 | 060T5 | 080T4 | 080T5 | 100T4 | 100T5 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| STEAM PRODUCTION | ||||||||||||

| Production capacity [kg/h] | 20 | 30 | 40 | 60 | 80 | 100 | ||||||

| Maximum pressure [mm H2O/Pa/bar] | 200/2000/0,02 | |||||||||||

| Pipe connection external diameter [mm] | 38 | |||||||||||

| STEAM DISTRIBUTION | ||||||||||||

| Number of linear distributors that can be connected [n] | 1 | 2 | ||||||||||

| Number of steam blowers that can be connected [n] | 2 | - | ||||||||||

| ELECTRICAL PROPERTIES | ||||||||||||

| Power consumption [kW] | 15 | 22.5 | 30 | 45 | 60 | 75 | ||||||

| Power supply [Vac, Hz] | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 | 400, 50/60 | 460, 50/60 |

| Phases [n] | 3 | |||||||||||

| Current per phase [A] | 21.7 | 18.8 | 32.5 | 28.2 | 43.3 | 37.7 | 65 | 56.5 | 86.6 | 75.3 | 108.3 | 94.1 |

| WATER PROPERTIES | ||||||||||||

| Inlet water quality | Complies with microbiological standards for drinking water established by regulations in force where installed. Partially demineralised water may be used | |||||||||||

| Inlet water conductivity [μS*cm] | 70…1250 | |||||||||||

| Inlet water hardness [°f] | 5...50 | |||||||||||

| Inlet water pressure [MPa/bar] | 0,2...1 / 2...10 | |||||||||||

| Minimum instantaneous flow rate of inlet water [l/min] | 3.5 | 2x3.5 | ||||||||||

| Inlet water connection | M 3/4"GAS | |||||||||||

| Water drain external dimensions [mm] | 40 | |||||||||||

| GENERAL CHARACTERISTICS | ||||||||||||

| Dimensions [mm] | 522x893x380 | 928x900x375 | ||||||||||

| Operating conditions [°C, RH] | 1…40, max. 80% non-condensing | |||||||||||

| Storage conditions [°C, RH] | -10…70, max. 95% non-condensing | |||||||||||

| Degree of protection | IP20 | |||||||||||

| REGULATION | ||||||||||||

| Type of controller | Built-in with advanced EPcolor user interface | |||||||||||

| Command signal | ON-OFF, proportional 0...10 V, transducer 0...10 V/4...20 mA | |||||||||||

| Connectivity | ||||||||||||

| RS485-MODBUS | Built-in | |||||||||||

| Linear steam distributors | |

| EHSD040T | linear steam distrubutor 400 mm long |

| EHSD060T | linear steam distrubutor 600 mm long |

| EHSD080T | linear steam distrubutor 800 mm long |

| EHSD100T | linear steam distrubutor 1.000 mm long |

| EHSD130T | linear steam distrubutor 1.300 mm long |

| EHSD160T | linear steam distrubutor 1.600 mm long |

| EHSD200T | linear steam distrubutor 2.000 mm long |

| EHSDP000 | linear steam distrubutor, measure on request |

| EHSD040X | linear steam distributor with thermal efficiency 400 mm long |

| EHSD060X | linear steam distributor with thermal efficiency 600 mm long |

| EHSD080X | linear steam distributor with thermal efficiency 800 mm long |

| EHSD100X | linear steam distributor with thermal efficiency 1.000 mm long |

| EHSD130X | linear steam distributor with thermal efficiency 1.300 mm long |

| EHSD160X | linear steam distributor with thermal efficiency 1.600 mm long |

| EHSD200X | linear steam distributor with thermal efficiency 2.000 mm long |

| EHSDP000X | linear steam distributor with thermal efficiency, measure on request |

| EHSDW022 | linear steam distributor with 22 mm nozzles |

| EHSR015M2 | steam blower (maximum 15 kg/h of steam) |

| EHSR0REM | stem blower support for remote installation |

| EHSDY038 | Y-shaped steam distribution fitting |

| EHSDC038 | right angle-shaped steam distribution fitting |

| EH090STEAM | right angle-shaped steam output fitting |

| EHTV038 | special steam piping that connects the humidifier and distributor (per meter) |

| EHTC010 | condensate drain hose from the distributor (per meter) |

| EHVI | drainage tank Zephyr, KT and VEH series humidifier |

| Regolazioni | |

| EV3411M7 | single output electronic controller, power supply 230 VAC, multi-sensor analog input |

| EVHTP520 | humidity and temperature probe, proprietary signal |

| EVHP523 | humidity transducer, power supply 8... 28 VDC, 1 x 4-20 mA provided signal |

| EVHTP523 | humidity and temperature transducer, power supply 8... 28 VDC, 2 x 4-20 mA provided signal |

| EVTPNW30F200 | NTC probe, 2 wires thermoplastic cable 3 m long, 5x20 mm overmoulded bulb, IP68 protection |

| EVTPN615F200 | NTC probe, 2 wires thermoplastic cable 1.5 m long, 6x15 mm overmoulded bulb |

| Vari | |

| 0031000048 | 0.3 m long flexible hose ¾ " GAS female that connects the mains water and solenoid valve to load water |

| EHFILLTANK | tank filling kit for high/low pressure |

| EH090DRAIN | right-angle water drain bend diameter 40 mm |

| EHKTBOTTOM15 | metal base for floor installation for EHKT003/EHKX003, EHKT005/EHKX005/EHKW005, EHKT010/EHKX010/EHKW010 and EHKT015/EHKX015/EHKW015 |

| EHKTBOTTOM40 | metal base for floor installation for EHKT020/EHKX020/EHKW020, EHKT030/EHKX030/EHKW030 and EHKT040/EHKX040/EHKW040 |

| EHKTBOTTOM100 | metal base for floor installation for EHKT060/EHKX060, EHKX080 and EHKX100 |

| EHKBLOCK15 | cable gland kit for EHKTBOTTOM15 |

| EHKBLOCK40 | cable gland kit for EHKTBOTTOM40 |

| EHKBLOCK100 | cable gland kit for EHKTBOTTOM100 |